Beef Quality Assurance Tent Method Subq Injections Cattle

Injection Sites

· 1995 Beefiness Quality Audit reported 11 percentage of carcasses had at least one injection site blemish

· The best site to give an injection isn't always the almost convenient

· Keep all injections in front of the shoulder

· Injection technique for both SC and IM injections

· Never inject more than 10cc into one site

· Don't re-inject into injection sites

· Minimize the risk of injection site reactions

The 1995 National Beef Quality Audit revealed eleven percent of the carcasses surveyed had at least one injection site blemish. The beef manufacture loses about $7.05 for each fed heifer or steer marketed due to injection site lesions. Not only can the injection site leave visible lesions, but there are besides meaning tenderness problems associated with lesion-afflicted lean tissue.

The recommended site for injections is not e'er the most user-friendly or easiest site to reach. The all-time location for an injection is the site where the product is the nearly beneficial, without the risk of dissentious the more expensive cuts of meat (upper rump and upper butt).

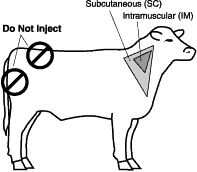

The 1995 National Beef Quality Audit suggests management changes to subtract the incidence of injection site lesions and reactions. First, producers should motion the location of injection sites from the top barrel and round to the neck, as shown in Figure 5, and use subcutaneous administration where the label allows. Producers should also discard burred or bent needles rather than reusing them. Figure five. Proper injection location.

Producers should pay particular attending to preparing their calves' immune systems through vaccinating. Programs that emphasize the importance of calf nutrition and timing of vaccinations tin can significantly reduce both the incidence of handling (and usually injection) for respiratory affliction and the incidence of excesses of multiple vaccinations, which tin can increase the incidence of injection site lesions.

Producers should pay particular attention to preparing their calves' allowed systems through vaccinating. Programs that emphasize the importance of dogie diet and timing of vaccinations can significantly reduce both the incidence of treatment (and ordinarily injection) for respiratory disease and the incidence of excesses of multiple vaccinations, which can increment the incidence of injection site lesions.

To reduce lost value of the expensive cuts of meat, go along all injections in front of the shoulder. NEVER INJECT INTO THE Pinnacle BUTT OR Tiptop OF THE RUMP!

For both vaccines and antibiotics, the triangular mass of cervix musculus is the preferred site for both IM and SC injections. Be certain to inject straight in, not at an bending, when giving IM injections. Use the tenting method for SC injections.

Never inject more than 10 cc into 1 site. When making multiple injections, keep injection sites at to the lowest degree 5 inches apart, being conscientious not to reuse injection sites. To minimize the risk of infection and incidence of injection site lesions, avoid injecting into wet or manure covered areas.

Administering Injections Properly

Steps in Administering Injections Properly

- Select the right product

- Read the label

- Don't combine vaccines

- Employ transfer needles

- Don't mix besides many products

- Keep shaking

- Mark and split up syringes

- Don't use disinfectants with modified alive vaccines

- Become air out of syringes

- Restrain animals properly

- Select best road of administration

- Choose all-time site of administration

- Choose the right needle

- Use proper injection technique

- Practice practiced sanitation

- Select the right product

When giving vaccinations; select the correct product for your need. This production should prevent futures infections or assist in stopping the electric current infection. In one case a production is selected, follow the label instructions.

- Read the label

The characterization of all health products will include 1) the dosage to exist given, 2) the timing of administration, and 3) the road of administration. The nigh common routes of assistants are intramuscular (IM), subcutaneous (SC), intravenous (4), intranasal (IN), and topical. Other less common methods are intramammary (IM), intrauterine (IA), intrarumenal (IR), and oral. The label will listing warnings, indications for use, and withdrawal times if any. The label volition likewise include proper methods of storage and disposal and expiration date.

- Don't combine vaccines

Mixing dissimilar vaccines could destroy the effectiveness and value of the private products. Use only canonical combinations.

- Employ transfer needles

Utilize transfer needles if a product needs to exist reconstituted. The apply of transfer needles should make the process easier and more sanitary. To use a transfer needle, place ane end of the needle into the sterile liquid or dilutant; the other end goes into the freeze-stale block of vaccine or bacterin. There should be a vacuum in the freeze-stale portion that immediately pulls the dilutent down.

- Don't mix too much of a product at once

Modified live vaccines (MLV) begin to degrade, or lose effectiveness, later nearly an hour. Mixing besides much product at one time may decrease effectiveness. For maximum effectiveness, mix enough vaccine for just one hour or less. Directly sunlight and extreme temperatures will also degrade the product, then it is all-time to keep it in a night absurd place, similar a cooler. Don't save leftover vaccine for later employ. Information technology won't be effective and could be contaminated. Dispose of all vaccine bottles and equipment properly.

- Keep shaking

When using large, multi-dose sizes of vaccine, such every bit a 200-dose bottle, mix thoroughly at beginning, and and then stop from time to time and milk shake the bottle again. If you lot don't keep mixing, the vaccine may settle, giving an inconsistent corporeality of antigen in each injection.

- Mark and separate syringes

Use and mark different syringes for bacterins or killed products. Mark the MLV syringes and keep them separate from the others. If traces of bacterin are left in a syringe that is later used for a modified live product, the bacterin could destroy the modified live vaccine, making it ineffective.

- Don't use disinfectants with MLV

Don't make clean syringes used for MLV with disinfectants. Use hot water to clean these syringes. Disinfectants tin can destroy MLV that you later on put in the same syringe. A mild disinfectant can be used for cleaning bacterin syringes, but be sure to rinse thoroughly.

- Get air out of syringes

To aid get the right dose of vaccine in the brute, remove whatsoever air that may be trapped in the syringe by pumping the grip slightly before filling. Afterward filling, pump it plenty to motion the vaccine upwardly to the needle tip so there is no trapped air that might be injected with the vaccine.

- Restrain animals properly

Restraining animals properly reduces the potential of hurting the animal or yourself. Proper restraint tin reduce the level of bruising to the animal. Bruising alone costs the cattle industry $22 1000000 per year.

- Select the best route of assistants

Selecting the best route of administration is crucial to effective vaccination. The 2 most mutual routes of administration are intramuscular (IM), which means injecting into the muscle, and subcutaneous (SC), which ways injecting nether the peel. Some products offer a selection, while others must be given in a specific way. The label will state the all-time method of administration. More often than not, bacterins or killed products can be given SC. Modified live virus products are usually given intramuscularly, considering this allows the virus to reproduce and reach the lymphatic organisation more than hands. Whenever possible, use the subcutaneous route if allowed on the label.

- Choose the best site of administration

Injection site lesions cost the industry most $7 per animal slaughtered. The best injection site is not necessarily the one that's the fastest or the easiest to get to. It is the site where the production will be the most effective, with the least possible risk of impairment to valuable cuts of meat. Give all injections in the neck. Never inject into the top butt or top of the rump.

- Utilize the correct needle

Choosing the correct needle may likewise lessen injection site lesions. When administering SC injections, use a 16 or eighteen-gauge needle, ½ to ¾ inch long. For IM injections, utilise a 16 or 18-gauge needle 1 to ane½ inch long, as shown in the table below. A 14-estimate needle isn't recommended - it is twice the diameter of a 16-gauge, which increases the risk of leakback and tissue harm.

If a needle is bent or broken, discard and replace with a new needle. Bent and broken needles increase the number of injection site lesions and increase the adventure of broken needles entering the nutrient supply.

- Utilize proper injection technique

When giving SubQ injections; tent the skin to get the product just under the skin and not into the musculus. Pull the skin abroad from the animate being'south body and insert the needle into the fold of pare. When giving multiple injections, keep injection sites several inches autonomously. Don't administrate more than 10 cc of product into any one site. If a product must be given several times over a menstruum of a few days, vary the injection site.

- Proper sanitation is essential

Good sanitation practices reduce the chance of spreading infection from 1 animal to another, the chance of contaminating the vaccine, and injection site reactions. Some basic steps to good sanitation include not going dorsum into the vaccine bottle with the same needle you use to vaccinate. Alter needles often, at to the lowest degree every 10 to 15 animals, or every syringe of vaccine. When using killed vaccines, go along a saucer or sponge of booze or disinfectant nearby and wipe off the needle later on each employ. Practise not disinfect needles between injections when using a modified live vaccine, as the disinfectant can destroy the vaccine. Injecting into a moisture or muddy site can increase both the spread of disease and the incidence of injection site lesions. Make certain the injection site is make clean. Clean transfer needles regularly to avoid contagion.

Correct Needle Size

Subcutaneous Intramuscular

½ to ¾ inch needle ane to 1 ½ inch needle

Cattle Weight Cattle weight

Injection Viscosity <300 300-700 >700 <300 300-700 >700

Sparse (needle gauge) xviii 18-xvi sixteen xx-18 18-xvi xviii-sixteen

Ex: Saline

Thick (needle gauge) xviii-16 18-16 sixteen eighteen 16 xvi

Ex: Oxytetracycline

Source: https://www.ag.ndsu.edu/bqa/documents/injections

0 Response to "Beef Quality Assurance Tent Method Subq Injections Cattle"

Post a Comment